Sustainability

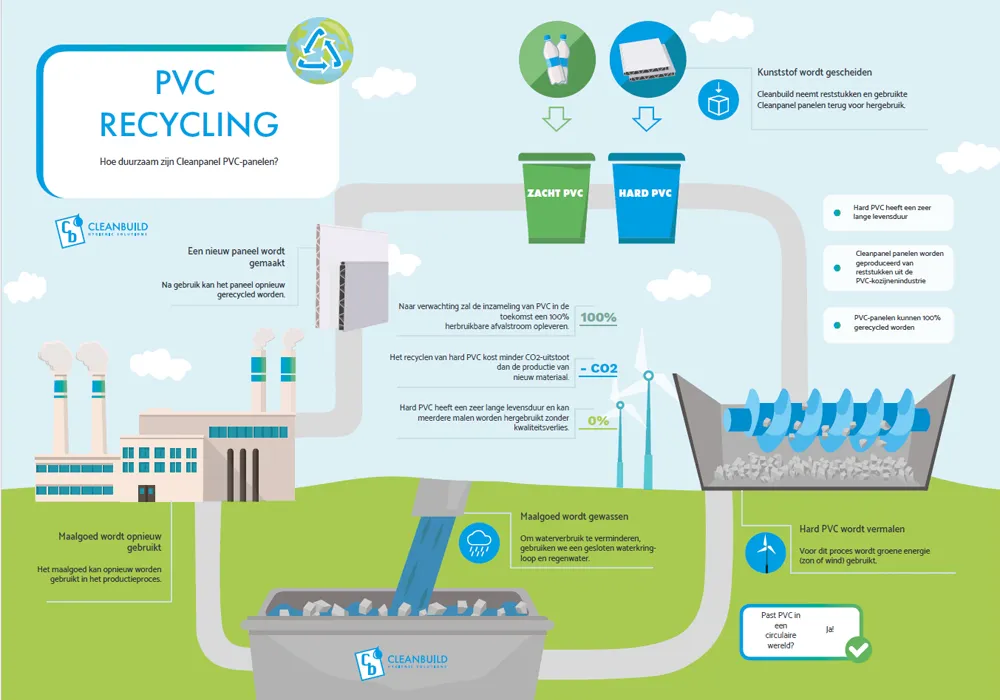

Sustainability and circularity are key concerns in the production process of Cleanpanel PVC panels. Although plastic may not seem sustainable, it fits into a circular economy. Hard PVC, of which Cleanpanel is made, has a very long lifespan. And after several decades of service, the panels can be recycled. We also use leftover PVC from the window frame industry in the production mix. Thus, the current generation of Cleanpanel panels already consists partly of recycled materials.

The infographic below shows how sustainability and reuse are applied in our production process.

Click here or on the image to download the PDF file.

Explanatory note

Over the last two decades, the PVC industry has made great progress in terms of recycling and systainalbility. It is now possible to recycle PVC 100% into new, fully-fledged products. Although the process still faces some challenges.

The recycling of PVC

PVC can be recycled in two ways: mechanically and chemically. In the recycling of Bouwplast panels, the mechanical method is used. This process roughly follows three steps

- Separation of rigid and soft PVC (and other types of plastic).

- Grinding the material into flakes.

- Washing and drying the grinding material.

After this process, the grinding material can be reused in the production process. The separation of the various types of plastics is challenging. The better the seperation, the higher the quality of the final product. PVC that is collected completely

homogeneously can be reused several times.

As the material has a long lifespan, it can be used as a high-quality building material for an exceptionally long time.

What about Cleanpanel?

Cleanpanel panels are made from leftover pieces from the plastic window industry. They already consist of recycled PVC. Cleanbuild also takes back residual pieces and used PVC panels for the production of new ones. The grinding material that is used in production, consists partly of our own products and is completely homogenous. This means it can be used in new PVC panels without any loss of quality.

Energy and CO2

Doesn’t the recycling of PVC cost more energy and CO2 emissions than the sourcing of new materials? No, it does not. Studies show that in the most ideal circumstances, recycling PVC costst up to 90% less energy than sourcing and applying new raw materials. Even if the recycling process is not optimal, recycling PVC is more eco-friendly than producing with raw material.

What about Cleanpanel?

To compensate for the extra energy used in the recycling process, we use green electricity. This is either generated by our own solar panels, or purchased from a green energy company. To wash the grinding material, water is also needed in the recycling process. To reduce water consumption, we use a closed water cycle in the plant which is replenished with rainwater.

Cleanpanel in a circular economy

PVC is already widely recycled. The technology is developing fast. It is realistic to expect that the collection and recycling of PVC will produce a fully reusable waste stream in the future. As the demand for strong and reusable building materials

increases, the construction sector is seen as a promising application oppertunity for recycled PVC.

The current waste system is not yet geared to 100% PVC recycling. We therefore take as many measures related to sustainability as possible ourselves. By collecting, grinding and reusing PVC, we integrate circularity into the production process. As a result, Cleanpanel plastic panels are already a sustainable building material.

Resources

- Stuurgroep PVC en Ketenbeheer, PVC Info, 27 juli 2023, https://www.pvcinfo.nl/duurzaamheid/recycling.

- De Federatie Nederlandse Rubber– en Kunststofindustrie NRK, NRK Recyling, 27 juli 2023, https://www.nrkrecycling.nl/onderwerpen/

- Braun, D., Reclycing of PVC, Progress in Polymer Science, 2002, 2171-2195

- Lewandowski, K., Skorczewska, K., A Brief Review of Poly(Vinyl Chloride) (PVC) Recycling, Polymers 2022, 14, 3035.

- Ignatyev, I.A., Thielemans, W., Vanderbeke, B., Reclycing of Polymers: A Review, ChemSusChem, mei 2014.

This information was written and published by Cleanbuild BV. No rights can be derived from the above.